Standard configuration:

- GSK controller

- Four station electrical tool post or gang type tool post

- collect

- manual tailstock

Optional configuration:

- Fanuc/Siemens/Mitsubishi controller

- Hydraulic chuck and hydraulic tailstock

- chip conveyor

- bar feeder

CNC lathe machine CK6136 with live tools and C axis spindle indexing

| ITM | unit | CK6136/CK6140 |

| Max. Swing over bed | MM | 360/400 |

| Max. Swing over cross slide | MM | 220 |

| Max. work length | Mm | 600/850 |

| Max. Z axis Travel | MM | 750/1000 |

| Max. X axis Travel | MM | 250 |

| Spindle bore | MM | 60 |

| Spindle nose | A2-6 | |

| Spindle speed range | RPM | 100-2500 |

| Spindle type | Independent spindle | |

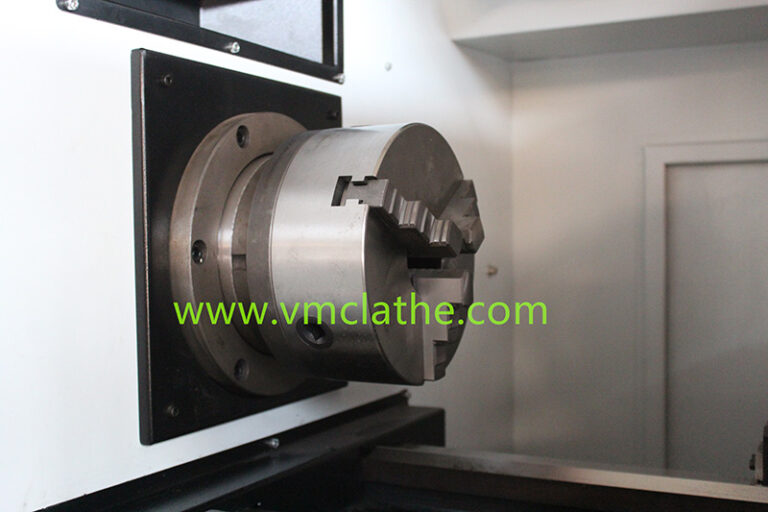

| Chuck | unit | manual 3 jaws 160mm |

| Bed width | MM | 330 |

| x/z fast feed | MM | 6000/8000 |

| x/z cutting travel speed | Mm/min | 1-6000 |

| Number of tool turret | Mm/min | 4/6/8 turret |

| Tool shank type | 20*20 | |

| Positioning accuracy | MM | X≤0.010 Z ≤0.015 |

| Repeatability Psoitioning accuracy | MM | X≤0.0075 Z ≤0.010 |

| Min. unit set | MM | 0.001 |

| roundness | MM | ≤0.007 |

| Diameter uniformity | MM | ≤0.03 (length 300) |

| Flatness | MM | ≤0.02 (Diameter 300) |

| Surface Roughness (Steel) | MM | Ra1.6um |

| Dia. of tailstock sleeve | Ra1.6um | 60 |

| Tailstock sleeve taper | MM | MT4 |

| Max. Tailstock sleeve travel | 140 | |

| Spindle drive motor power | MM | 5.5 |

| Coolant pump power | KW | 120 |

| size | W | 2150X1400X1600 |

| weight | 1.7T |

Motor shafts are critical components in electric motors, responsible for torque transmission and accurate positioning of rotating parts. The machining accuracy of motor shafts—especially diameter tolerance, concentricity, and surface finish—directly affects motor stability, noise level, and service life. For many standard motor shaft applications, flat bed CNC lathes are widely used due to their stable […]

Key Process Steps in Drive Shaft Machining 1. Blank Preparation and Clamping A. Blank Selection: Select hot-rolled round steel (e.g., 60mm diameter, 250mm length) based on the drive shaft dimensions. The material is typically 45 steel, which meets general transmission requirements. B. Clamping Plan: a) First Clamping: Clamp the outer diameter of the blank using […]

Flat-bed CNC lathes, with their advantages of high precision, high efficiency, and flexibility, combined with rational process design, can meet the machining needs of shaft parts. However, consideration should be given to the limitations of the machine’s rigid counterweight cutting and vibration control. The following is a detailed analysis of their use in shaft part […]

1. What is a power head? What is its core value? A. Definition: A power head is a standalone module mounted on the CNC lathe’s tool turret. Its tool has its own rotational power (driven by a servo motor), rather than relying solely on spindle rotation. It allows the machine to perform axial or radial […]

1. Determine the processing needs and precision requirements: a) Processing accuracy: According to the precision requirements of the workpiece to be processed, select a CNC lathe with corresponding positioning accuracy and repeat positioning accuracy. b) Surface roughness: Consider the surface roughness required for the workpiece to be processed and select a machine tool that can […]

Selecting the right spindle hole size and flat bed CNC lathe selection requires comprehensive consideration of factors such as workpiece size, processing accuracy, machine tool structure and performance. The following is a specific guide: 1. Clarify the processing requirements: a) Workpiece size: According to the maximum diameter and length of the workpiece to be processed, […]

Choosing a CNC lathe for metal processing is a decision-making process that requires comprehensive consideration of many factors. The following is a practical guide to help you choose the right equipment according to your actual needs. 1. Clarify processing needs and goals a) Processing materials Determine the type of metal material (such as steel, aluminum, […]

When choosing a CNC lathe suitable for mass production, you need to focus on the equipment’s production efficiency, stability, degree of automation and long-term maintenance costs. Here are some key factors and suggestions to help you make a wise choice: ________________________________________ 1. Production efficiency (1) Spindle speed and power A. High speed: Choose a lathe […]

When purchasing a CNC lathe, you need to focus on the following technical parameters to ensure that the equipment can meet the processing requirements and has a high cost-effectiveness: 1. Machine tool specifications (1) Processing range Maximum processing diameter: determines the maximum workpiece diameter that the machine tool can handle. Maximum processing length: determines the […]