Choosing a slant bed CNC lathe with powered toolholder is a wise move to improve processing efficiency and precision. Here are five reasons to choose this type of lathe:

1. High-precision processing capability:

1) The slant bed design itself provides higher rigidity and stability, reduces vibration, and thus ensures high precision during processing.

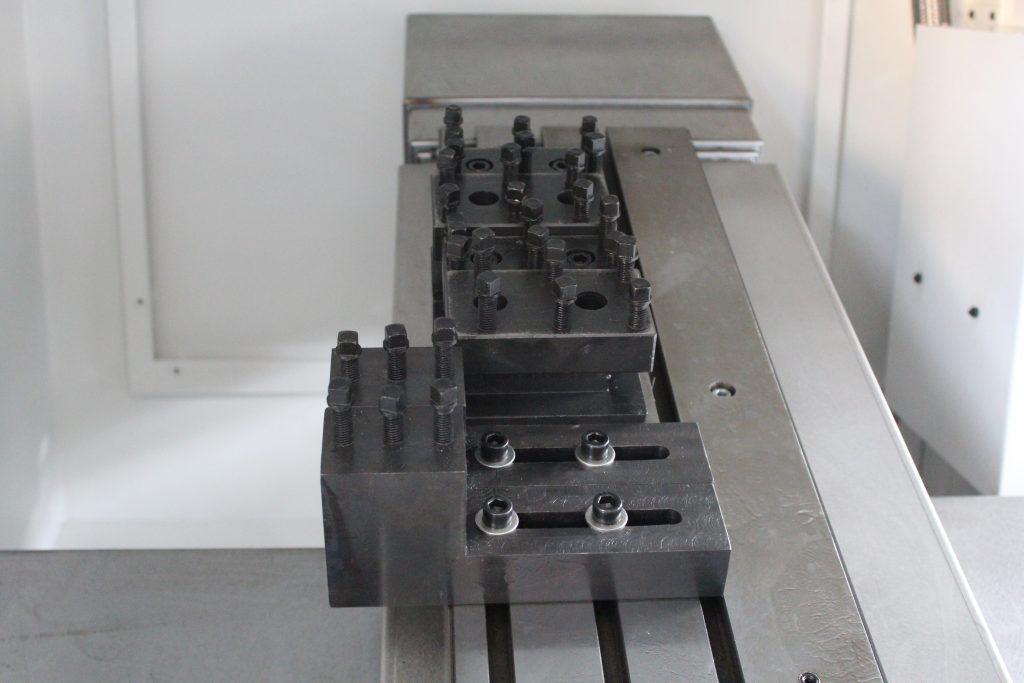

2) The powered toolholder can automatically adjust the tool position and angle to achieve more refined processing control and meet the precision manufacturing needs of complex parts.

2. High efficiency processing efficiency:

1) The powered toolholder supports fast tool change and automatic feeding, which significantly shortens the processing cycle and improves production efficiency.

2) The slant bed structure makes the tool path more optimized, reduces invalid movement, and further improves processing efficiency.

3. Wide range of processing:

1) CNC lathes with powered toolholders can process a variety of materials and parts of different shapes, including hard metals, non-metallic composite materials, etc.

2) The slanted bed design enables the lathe to handle larger workpieces and increases the flexibility of the processing range.

4. Good operating experience:

1) CNC systems are usually equipped with advanced user interfaces, making programming and operation more intuitive and simple.

2) The slanted bed design provides a better operator view, making it easier to observe and monitor the processing process to ensure processing quality and safety.

5. Long-term stability and durability:

1) The slanted bed structure is sturdy and can withstand long-term heavy-load processing, reducing the wear and failure rate of the machine tool.

2) The power tool holder is made of high-quality materials, has excellent durability and reliability, can operate stably for a long time, and reduces maintenance costs.

In summary, the slanted bed CNC lathe with a power tool holder has become an ideal choice for many manufacturing companies to improve their processing capabilities and market competitiveness with its high precision, high efficiency, wide processing range, good operating experience, long-term stability and durability. When choosing, you also need to consider factors such as specific application requirements, budget, and supplier services and support.