1. What is a power head? What is its core value?

A. Definition:

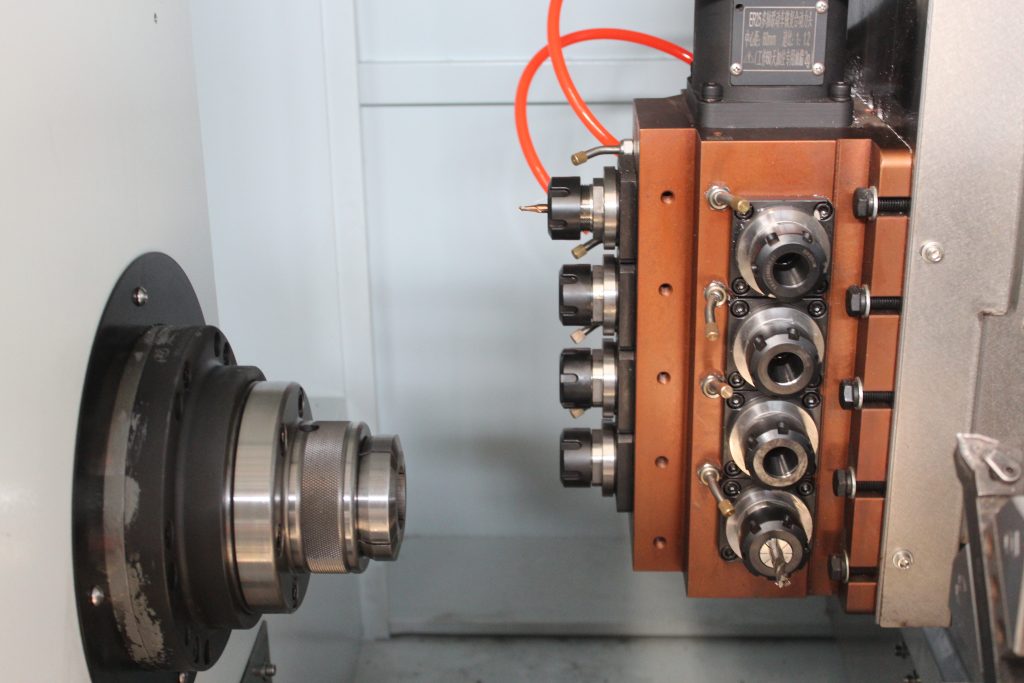

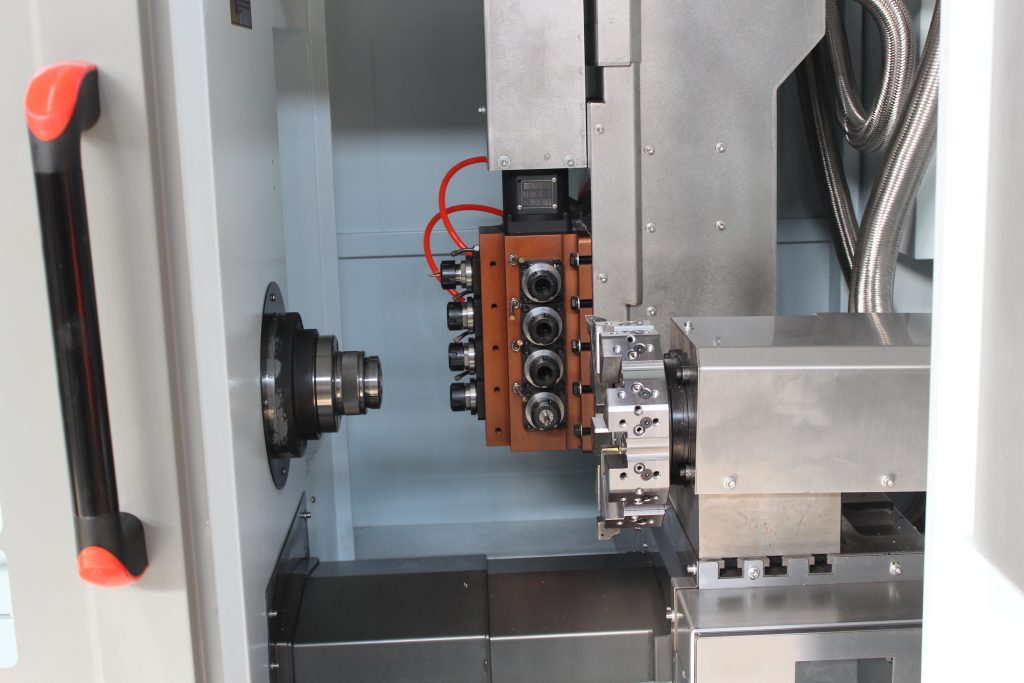

A power head is a standalone module mounted on the CNC lathe’s tool turret. Its tool has its own rotational power (driven by a servo motor), rather than relying solely on spindle rotation. It allows the machine to perform axial or radial milling and drilling operations while the spindle (workpiece) is stationary or rotating.

B. Core Value: Keys to Improving Performance:

a) Reduced Setups: In traditional machining, a part may be turned first and then transferred to the milling machine for keyway or hole processing. A power head allows all these steps to be completed in a single setup, which is its greatest advantage.

b) Improved Machining Accuracy: Multiple setups inevitably result in repeatability errors. A single setup ensures the positional accuracy and concentricity of all machined surfaces, significantly improving overall part quality.

c) Significantly Reduced Machining Time: By eliminating auxiliary time such as part handling, re-clamping, and tool setting, production efficiency can be increased by over 30% or even several times. d) Reduced Costs and Floor Space: A single turning center with a power head can replace multiple conventional machine tools (lathes, milling machines, and drilling machines), reducing equipment investment, floor space, and labor costs.

e) Complex Part Processing: This makes it possible to process complex, special-shaped parts (such as shaft sleeves with eccentric holes, radial holes, curved surfaces, and keyways) on CNC lathes.

________________________________________

2. How to Choose a Power Head? (Key Points for Selection)

Choosing a power head is a systematic process that should be determined based on your machining requirements, budget, and existing machine tool conditions. The following are key considerations:

a) Drive Type:

B. Servo Motor Direct Drive:

a) Advantages: Compact structure, short drive train, good rigidity, high precision, high speed (up to 10,000 rpm), and low vibration.

b) Disadvantages: Relatively low torque and higher cost.

c) Applications: Light cutting and high-precision applications such as high-speed precision milling, small hole drilling, and precision tapping. C. Servo Motor + Gearbox Drive:

a) Advantages: High output torque, powerful power, suitable for heavy cutting.

b) Disadvantages: Complex structure, backlash, low speed (usually a few thousand rpm), high noise and vibration.

c) Applications: Large-diameter drilling, slot milling, and heavy milling operations.

d) Tool Interface Type:

D. VDI: This type features a cylindrical shank with a cam lock at the end of the toolholder, offering excellent rigidity and repeatability during tool changes. This is the mainstream type.

E. BMT: The toolholder is positioned via an end gear, providing excellent connection rigidity and stability. This type is particularly suitable for heavy cutting and high-precision applications.

F. Other types: These include CAPTO and HSK, and are primarily used in specific high-end applications.

a) Selection Criteria: The interface must match the machine tool turret, and consider rigidity, precision, and tool cost.

b) Performance Parameters:

G. Maximum Speed (rpm): This determines how small the diameter can be drilled and how efficient the milling can be. High speeds are required for machining non-ferrous metals such as aluminum. H. Maximum Torque (Nm): This determines how heavy the cuts the drive unit can perform, such as large-diameter drilling or slotting steel.

I. Power (kW): This relates to torque and speed, and comprehensively reflects the cutting capabilities of the drive unit.

a) Selection Basis: Balance speed and torque requirements based on the materials you most commonly machine (aluminum, steel, cast iron?) and typical operations (drilling small holes or milling large slots?). “High Speed, Low Torque” and “Low Speed, High Torque” are two typical configurations.

b) Cooling Method:

J. External Coolant: This is the standard configuration, with coolant injected externally through the tool.

K. Through-Tool Coolant: This allows coolant to flow directly from the tool tip through the toolholder’s bore. This is crucial for deep-hole drilling, providing effective chip evacuation and cooling, significantly improving tool life and machining quality. This option is essential for high-end applications. a) Brand and Budget:

L. European/American/Japanese brands: Such as Germany’s OTT and JUNKER, Italy’s DUPLOMATIC, and Japan’s NT. They offer mature technology, reliable performance, and high precision, but are expensive.

M. Taiwanese/Mainland Chinese brands: Such as Delta and Litz. They offer high cost-effectiveness, convenient after-sales service, and rapid technological advancement in recent years, making them the preferred choice for most users.

a) Selection Criteria: Within your budget, prioritize brands with high reliability and excellent after-sales service.

________________________________________

3. Power Unit Application Scenarios (How to Improve Performance)

The use of power units greatly expands the capabilities of CNC lathes:

A. Axial Machining:

a) Face Drilling/Tapping: Processing holes on the end face of a part.

b) Face Milling: Milling flat surfaces, contours, or cavities on the end face.

c) Face Engraving: Engraving logos and text on the end face of a part. B. Radial Machining:

a) Radial Drilling/Tapping: Machines vertical holes on the cylindrical surface of a part, which is impossible on traditional lathes.

b) Keyway Milling: Mills keyways on shafts.

c) Flattening: Machines flat squares or drive planes on shafts.

d) Eccentric/Angled Machining: By linking the C-axis (spindle indexing) with the spindle head, holes or slots that are not on the same circumference can be machined.

C. Complex Surface Machining (C-axis and Y-axis linkage):

a) On more advanced milling centers equipped with a Y-axis and a powerful CNC system, the spindle head can interpolate with the C-axis, enabling eccentric contour milling and even extremely complex three-dimensional surfaces such as impellers and human figures.

________________________________________

4. Selection and Application Summary: Decision-Making Process

A. Define the machining requirements: What part do I need to machine? What material is it made of? What milling/drilling operations are required? (For example: Do I need to mill hexagons? Do I need to drill radial holes?)

B. Evaluate the existing machine: Does my machine’s turret support a powered head? (Check the machine manual.) Is the interface VDI or BMT? What is the performance of the machine’s C-axis (spindle indexing)? Does the system support milling?

C. Determine performance parameters: Determine the required speed, torque, and cooling method based on your needs. (For example: Machining small holes in aluminum alloys requires high speed and center-discharge water; machining slots in steel requires high torque.)

D. Set a budget and select a brand: Within your budget, choose the brand and model with the highest reliability and best after-sales service.

E. Programming and operator training: Using a powered head requires programming with CAM software (such as Mastercam, UG, etc.) or the use of macro programs. Operators also require training to understand its operating principles and maintenance procedures.

Conclusion

The powered head is a core upgrade option for CNC lathes to achieve efficient, precise, and complex machining. The correct selection and application of a power head not only solves specific processing challenges but also reshapes the overall production process, achieving comprehensive optimization of quality, efficiency, and cost. This is a powerful tool for enhancing competitiveness in the modern manufacturing industry. When making decisions, thorough technical research and needs analysis are essential to ensure maximum return on investment.