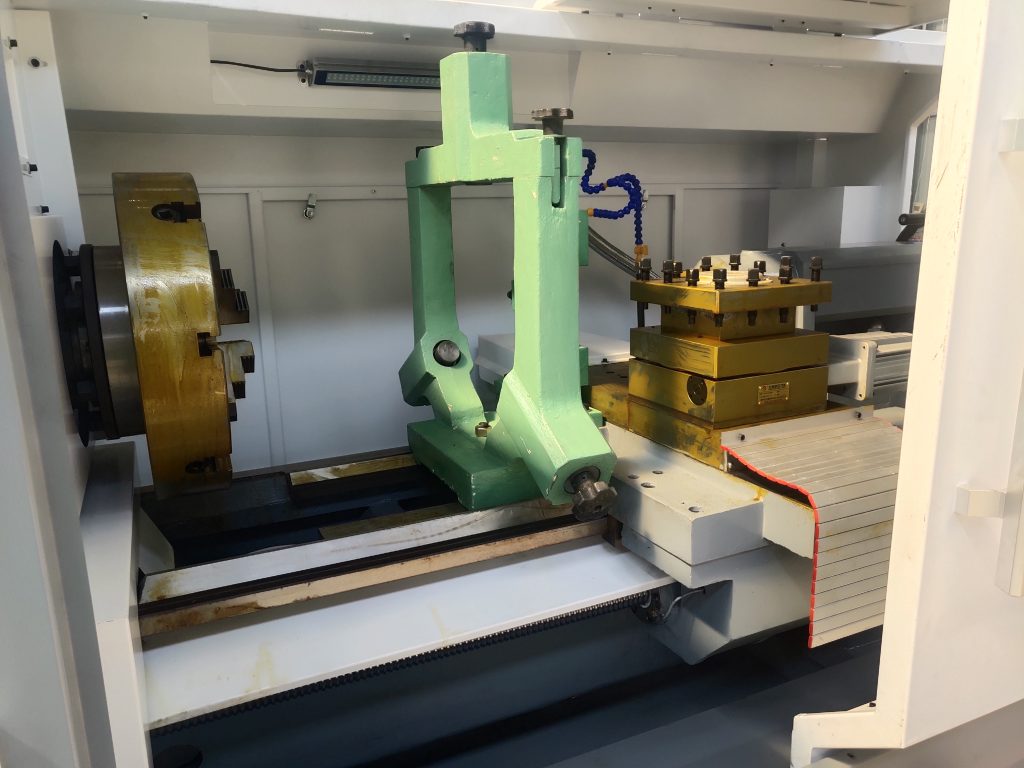

Automatic feeder is widely used in flat bed CNC lathe, and its functions and effects are mainly reflected in the following aspects:

Application background

With the continuous development of industrial technology, CNC lathes are more and more widely used in manufacturing. In order to improve production efficiency, reduce labor costs and ensure processing accuracy, automatic feeders are widely used in flat bed CNC lathes. This equipment can realize automatic feeding, positioning and unloading of workpieces, thereby greatly improving the automation level of the production line.

1. Main functions

1) Automatic feeding:

a) The automatic feeder can accurately feed the workpiece from the raw material area to the processing area of the CNC lathe, reducing the time of manual feeding.

b) Suitable for workpieces of various shapes and sizes, including round bars, hexagonal materials, hollow materials, etc.

2) High-precision positioning:

a) The use of a precise positioning system can ensure the accurate position of the workpiece during the processing process.

b) This helps to ensure the accuracy and consistency of processing and improve product quality.

3) Unloading after processing:

a) After processing, the automatic feeder can unload the workpiece from the processing area to facilitate subsequent processing.

4) Adaptability and flexibility:

a) The automatic feeder can usually adjust parameters according to different processing requirements to adapt to the processing requirements of a variety of different workpieces.

b) This enables it to perform well in different production environments.

2. Application effect

1) Improve production efficiency:

a) The automatic feeder can greatly reduce the time of manual operation and improve production efficiency.

b) This helps companies reduce production costs and improve market competitiveness.

2) Ensure processing accuracy:

a) Since the automatic feeder uses a precise positioning system, it can ensure the accuracy and consistency of processing.

b) This helps companies improve product quality and meet higher customer demands.

3) Save human resources:

a) The application of the automatic feeder greatly reduces the need for manual operation and reduces the labor intensity of workers.

b) This helps companies improve the working environment and improve employee job satisfaction.

4) Easy to maintain and service:

a) The structure of the automatic feeder is usually simple and easy to maintain and service.

b) This helps enterprises reduce the equipment failure rate and improve the reliability and stability of the equipment.

3. Application Examples

In practical applications, automatic feeders have been successfully used in many fields such as automobile manufacturing, mechanical processing, and electronic equipment. For example, in the field of automobile manufacturing, automatic feeders can realize automatic feeding and positioning of automobile parts, greatly improving the automation level and production efficiency of the production line. In the field of mechanical processing, automatic feeders can realize automatic feeding and processing of workpieces of various shapes and sizes, improving processing accuracy and product quality.

In summary, the application of automatic feeders in flat bed CNC lathes has significant advantages and effects. With the continuous development of industrial technology, automatic feeders will be widely used and promoted in more fields.