Compared with traditional flat bed CNC lathes, slant bed CNC lathes have significant technical advantages. The following are the five technical advantages of slant bed CNC lathes

1. High precision:

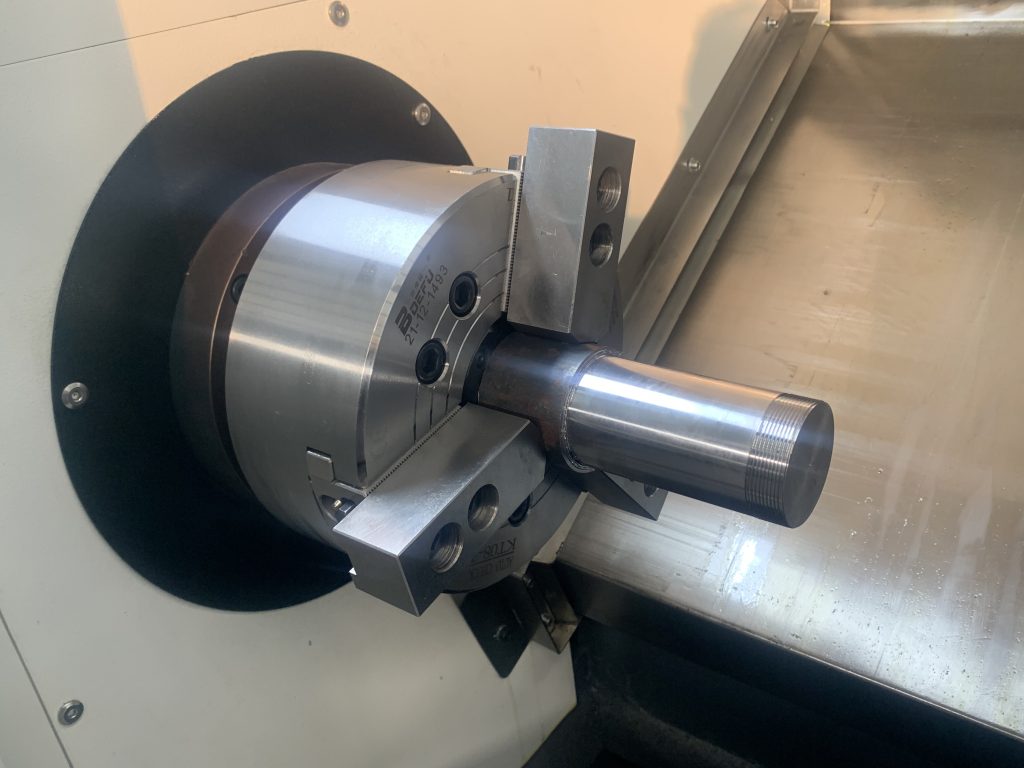

A. Slant bed CNC lathes use high-precision ball screws and linear guides to ensure the positioning accuracy and repeat positioning accuracy of the machine tool coordinate axis.

B. Advanced thermal compensation technology effectively reduces the error caused by thermal deformation of the machine tool, and further ensures the dimensional accuracy and surface quality of the processed parts.

2. High rigidity:

A. The inclined design of the bed guide rails makes the slant bed CNC lathe have a large load section, strong bending and torsion resistance, and good rigidity and shock absorption performance.

B. The bed is made of high-grade cast iron material, which is precision cast and processed to further enhance the rigidity of the machine tool.

3. Good chip removal performance:

A. The inclined guide rail design allows the chips generated during the processing to be discharged quickly and smoothly, reducing the interference of chip accumulation on the processing.

B. Good chip removal performance improves the continuity and stability of processing, which helps to improve processing efficiency and part quality.

4. High processing efficiency:

A. The slant bed CNC lathe has a small spindle traction torque and a high spindle speed, which is suitable for high-speed cutting.

B. The machine tool is equipped with a multi-station turret or a power turret, has a wide range of process performance, can process various complex workpieces, and improves processing efficiency.

5. Strong adaptability:

A. Slant bed CNC lathes can be widely used in aerospace, military, automobile, mold and other industries to meet the processing needs of various high-precision and complex shape parts.

B. The machine tool adopts an advanced CNC system to achieve precise control of the processing process. Operators can set various complex processing paths and cutting parameters through programming, which improves the flexibility and adaptability of processing.

In summary, the slant bed CNC lathe plays an increasingly important role in the modern manufacturing industry with its technical advantages such as high precision, high rigidity, good chip removal performance, high processing efficiency and wide adaptability.