Selecting the right spindle hole size and flat bed CNC lathe selection requires comprehensive consideration of factors such as workpiece size, processing accuracy, machine tool structure and performance. The following is a specific guide:

1. Clarify the processing requirements:

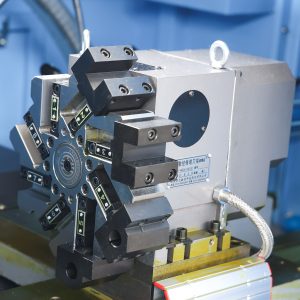

a) Workpiece size: According to the maximum diameter and length of the workpiece to be processed, select a CNC lathe with sufficient spindle hole size and processing stroke. For example, if you need to process a workpiece with a larger diameter, you should choose a lathe with a larger spindle hole size.

b) Processing type: Consider whether you need to process long bars or tubes, which determines the passing capacity of the spindle hole. For situations where you need to process long bars, you should choose a lathe with a larger spindle hole size and sufficient processing length.

2. Consider machine tool performance:

a) Spindle power and torque: Lathes with larger spindle hole sizes are usually equipped with spindles with higher power and torque to meet the processing needs of heavy cutting and large workpieces.

b) Speed range: According to the processing material and process requirements, select a spindle with a suitable speed range. For example, when processing high-strength materials, a lower spindle speed may be required to obtain sufficient cutting force.

3. Understand the mainstream products in the market:

a) Common spindle hole sizes: The spindle hole sizes of flat-bed CNC lathes on the market vary, such as 82mm, 120mm to 530mm. Choose the appropriate spindle hole size according to specific needs.

b) Product cases: You can refer to some specific models of lathes, such as the spindle through-hole diameter of the CK6150 CNC lathe is 65mm or 82mm (may vary in different configurations), which is suitable for processing workpieces within a certain size range.