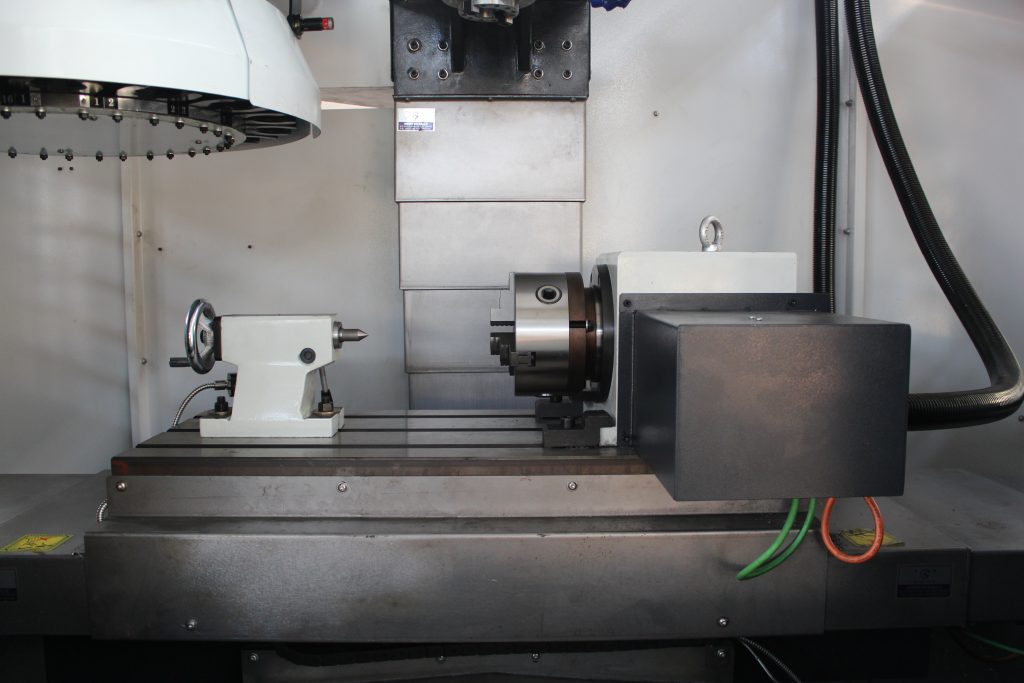

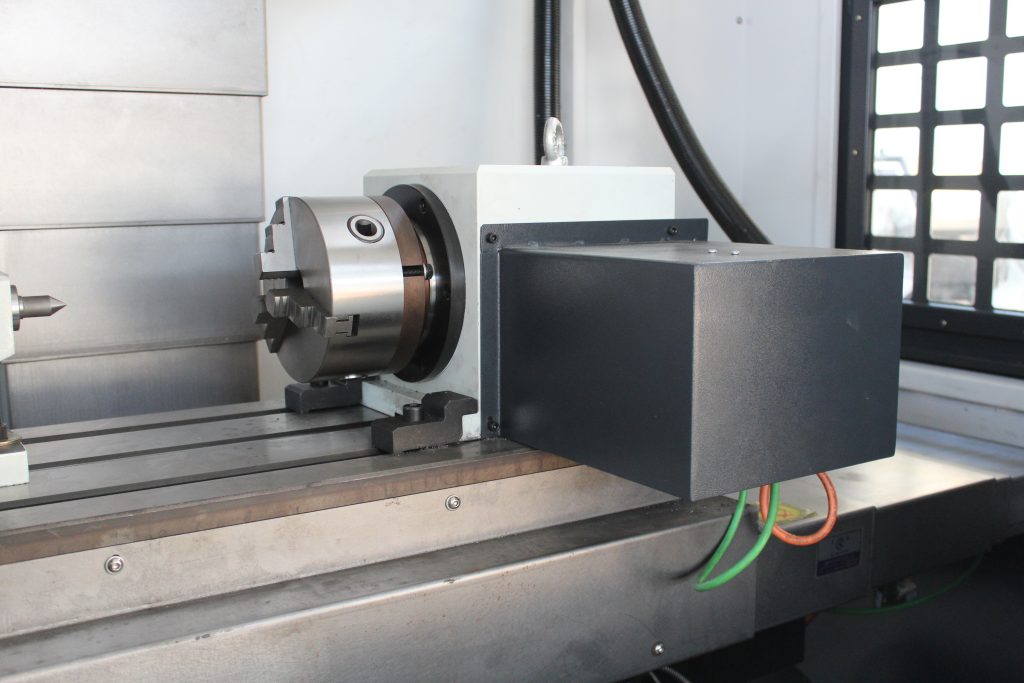

As a high-performance CNC machining equipment, the four-axis CNC machining center adds a rotary axis (usually called A-axis, B-axis or C-axis) to the traditional three-axis machining center, which significantly improves its machining capacity and adaptability. The following is a detailed analysis of the performance of the four-axis CNC machining center:

1. High-precision machining

A. Multi-face machining capability: Due to the addition of a rotary axis, the four-axis machining center can complete the machining of multiple faces of the workpiece in one clamping. This reduces the error caused by repeated clamping of the workpiece, thereby improving the machining accuracy.

B. Complex geometry machining: The four-axis machining center can achieve depth and angle limit machining that three-axis machine tools cannot complete, such as the machining of complex parts such as fan blades and worms. These parts often have high precision requirements, and the four-axis machining center can meet these requirements.

2 High efficiency

A. Automatic tool changing function: The four-axis machining center is usually equipped with an automatic tool changing system, which can complete multiple machining functions in one clamping. This improves machining efficiency and flexibility and reduces the time for clamping and tool setting.

B. Rapid moving speed: The X, Y, and Z axes of the four-axis machining center usually use roller linear guides and high-precision ball screws, which have high rigidity and low noise, can achieve rapid displacement and obtain cycle accuracy. For example, the rapid moving speed of some four-axis machining centers can reach 48m/min, which significantly improves the machining efficiency.

3. Flexibility and adaptability

A. Multi-axis linkage control: The four-axis machining center can realize multi-axis linkage control, which makes it more flexible when machining complex surfaces. Whether it is a vertical or horizontal four-axis machining center, it can rotate on the Y-axis or A-axis to meet the machining needs of different angles and complex geometric shapes.

B. Wide applicability: The four-axis machining center is suitable for machining various complex parts, especially in depth and angle limit machining. It has obvious advantages. It has been widely used in many fields such as machinery manufacturing, mold processing, and automotive accessories.

4. Other performance characteristics

A. Heavy-duty structure: The four-axis machining center usually adopts a heavy-duty box-type structure with internal rib reinforcement, high rigidity, and can withstand large cutting forces.

B. Spindle performance: The spindle has various rotation modes, such as belt connection, and the maximum speed can reach 12,000 rpm or higher. The spindle cutting method adopts a pneumatic mechanism, and the spindle is evenly stressed during cutting, which prolongs the life of the bearing.

C. Electrical system: The electrical box adopts an internal isolation design to separate the heat source part of the controller, with good heat dissipation performance to prevent external dust from entering the electrical box.

D. Programming and operation: The programming work of the four-axis machining center is relatively complicated, and it is necessary to carefully plan the motion trajectory of the rotating axis and ensure the coordination and cooperation between the four axes and other axes. At the same time, higher skill requirements are also put forward for operators.

In summary, the four-axis CNC machining center plays an increasingly important role in modern manufacturing with its high precision, high efficiency, flexibility and adaptability and other excellent performance characteristics.