The debugging tips for the Y-axis of a slant-bed CNC lathe are essential for improving machining accuracy. Here are some specific debugging tips and strategies to help optimize the performance and machining accuracy of the Y-axis:

-

Mechanical adjustment and maintenance:

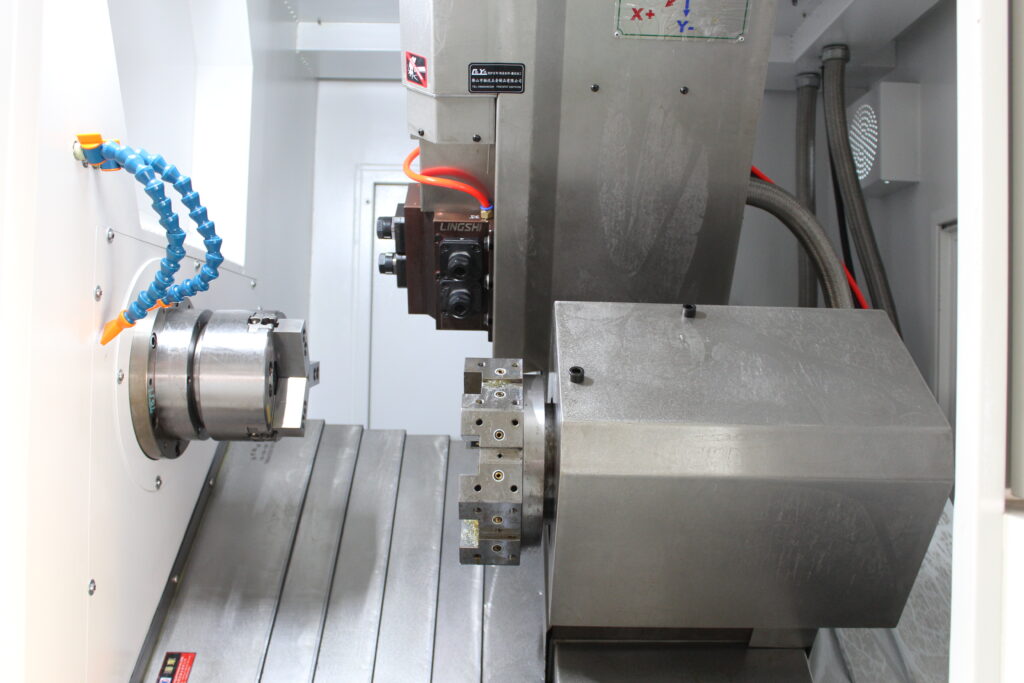

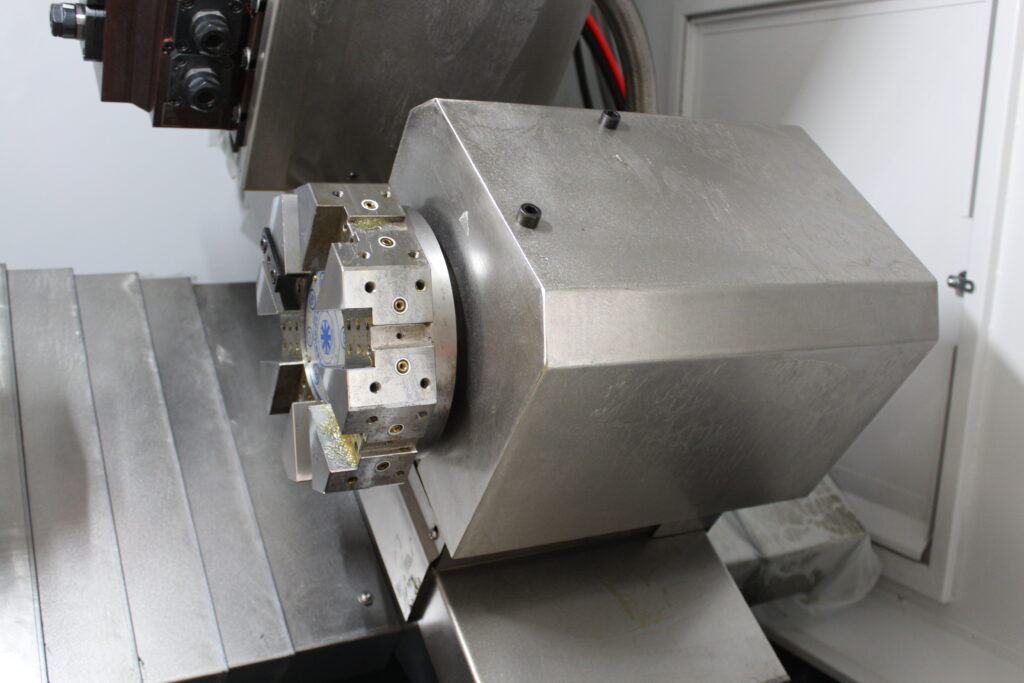

o Y-axis guideway inspection: Ensure that the straightness, horizontality, and parallelism of the Y-axis guideway are within the allowable range. Use high-precision measuring tools to regularly check the accuracy of the guideway and make necessary adjustments.

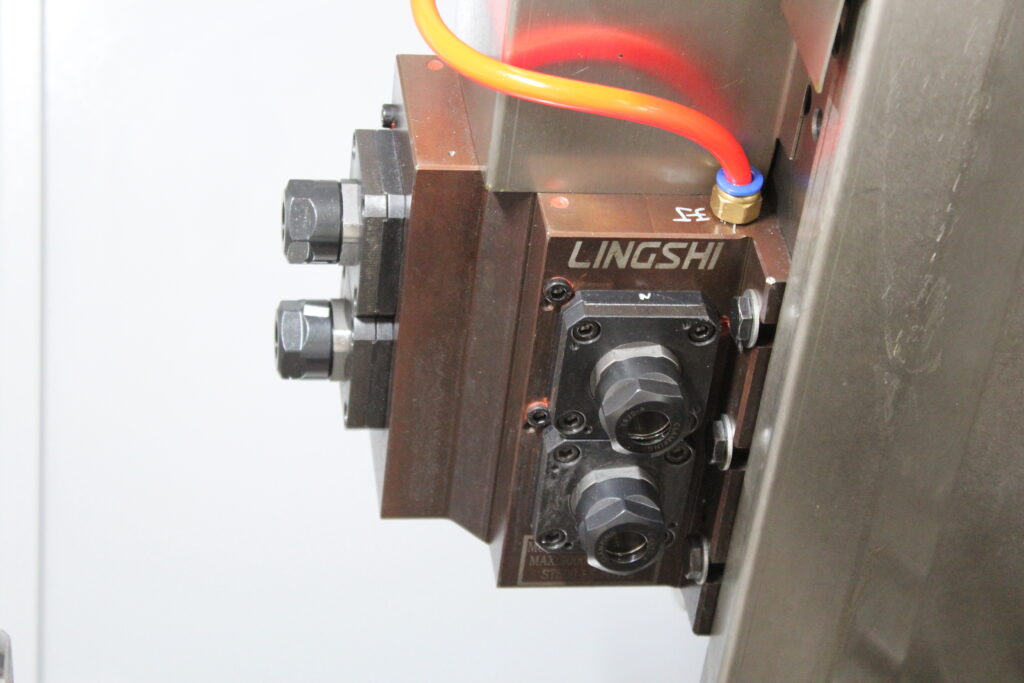

o Inserts and connecting parts: Accurately adjust the gap between the inserts to ensure the relative position accuracy between the components of the Y-axis. This helps reduce errors caused by loose components or excessive gaps.

o Lubrication and cleaning: Keep the Y-axis guideway and transmission components in good lubrication and clean condition. Clean the dirt and debris on the guideway regularly and lubricate with appropriate lubricating oil or grease.

-

Y-axis drive system inspection:

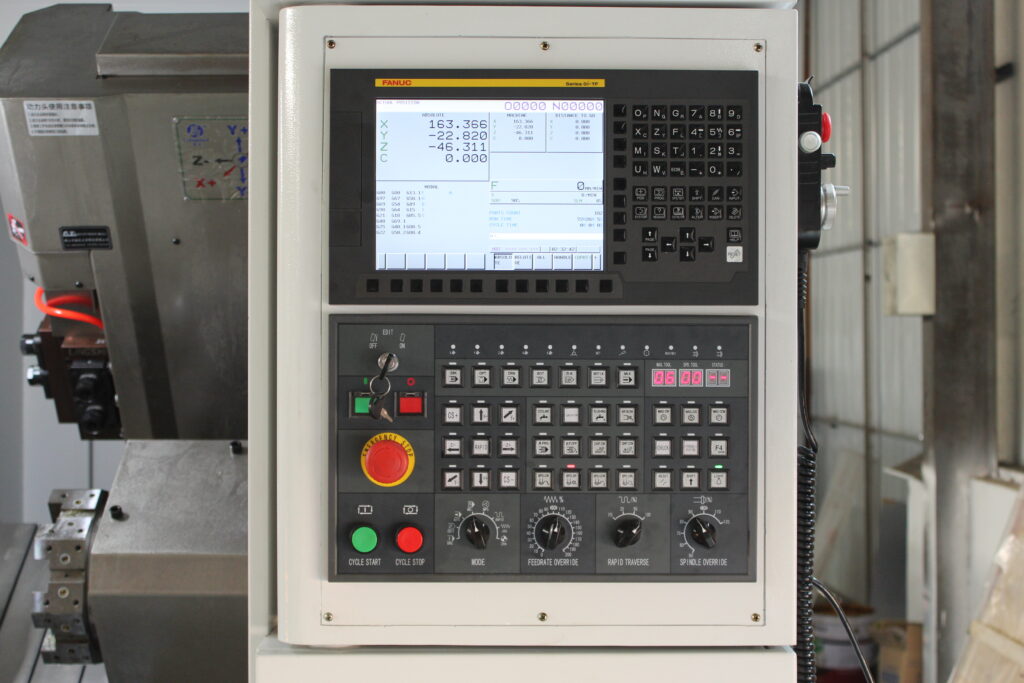

o Servo motor parameter optimization: According to the actual situation of the machine tool, optimize the parameter settings of the servo motor, such as gain, dynamic response characteristics, etc. This helps to improve the motion accuracy and stability of the Y-axis.

o Encoder calibration: Ensure the high resolution and accuracy of the Y-axis encoder. Calibrate the encoder regularly to eliminate or reduce positioning accuracy problems caused by encoder errors.

-

Error compensation technology:

o Reverse deviation compensation: Measure the reverse clearance (return clearance) of the Y axis and enter the corresponding compensation value in the CNC system. This helps to eliminate or reduce positioning errors caused by clearance in the transmission chain.

o Geometric error compensation: Use the error compensation function of modern CNC systems to compensate for the geometric shape errors of the Y axis in real time. This helps to improve the machining accuracy and stability of the Y axis.

-

Temperature control:

o Machine tool temperature control measures: Implement machine tool temperature control measures, such as installing cooling devices, constant temperature workshops, or using materials with low thermal expansion coefficients to manufacture key components. This helps to reduce the Y axis accuracy drift caused by temperature changes.

-

Programming and process optimization:

o Reasonable selection of cutting parameters: Avoid excessive cutting forces that cause Y axis deformation or increased errors. Select appropriate cutting parameters according to the workpiece material and machine tool performance.

o Optimize tool path planning: Reduce the cumulative error generated during continuous cutting. Improve machining efficiency and accuracy by optimizing tool path planning.

-

Daily maintenance and monitoring:

o Regular accuracy inspection: Regularly inspect and calibrate the accuracy of the Y-axis. This helps to detect and fix potential problems in a timely manner and maintain the high accuracy of the Y-axis.

o Preventive maintenance: Use various diagnostic tools to monitor the machine tool status and achieve preventive maintenance. Ensure the stability and reliability of the Y-axis through regular inspection and maintenance.

The above comprehensive means can effectively improve the machining accuracy and stability of the Y-axis of the inclined bed CNC lathe. In actual operation, it is necessary to flexibly adjust and optimize according to the actual situation of the machine tool and processing requirements.