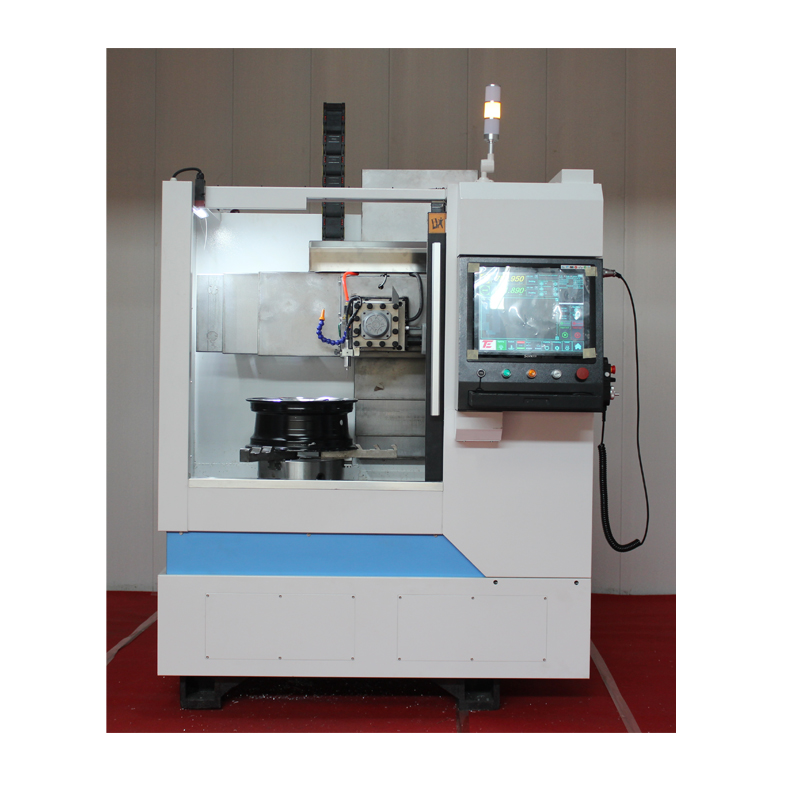

1. Working principle

The working principle of wheel hub repair surface cutting lathe usually includes the following steps:

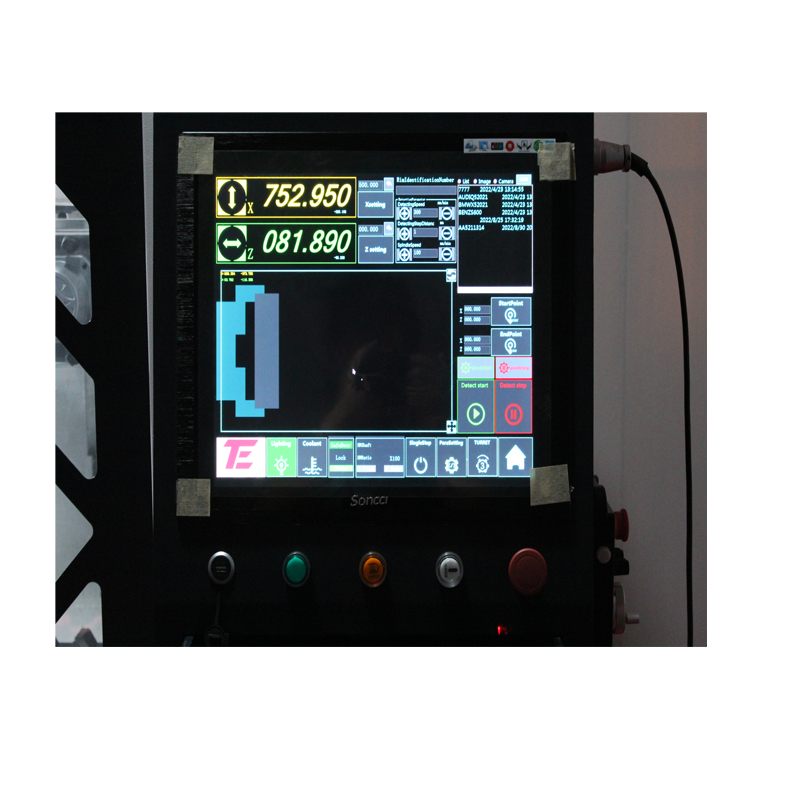

1) Detection track: Use the probe to automatically detect the damage track of the wheel hub surface and obtain the track program.

2) Data processing: Through the data processing system, the detected track data is converted into the G code required for processing.

3) Cutting repair: According to the G code, the cutting tool of the lathe performs precise cutting repair on the wheel hub surface to achieve the purpose of restoring the flatness and aesthetics of the wheel hub surface.

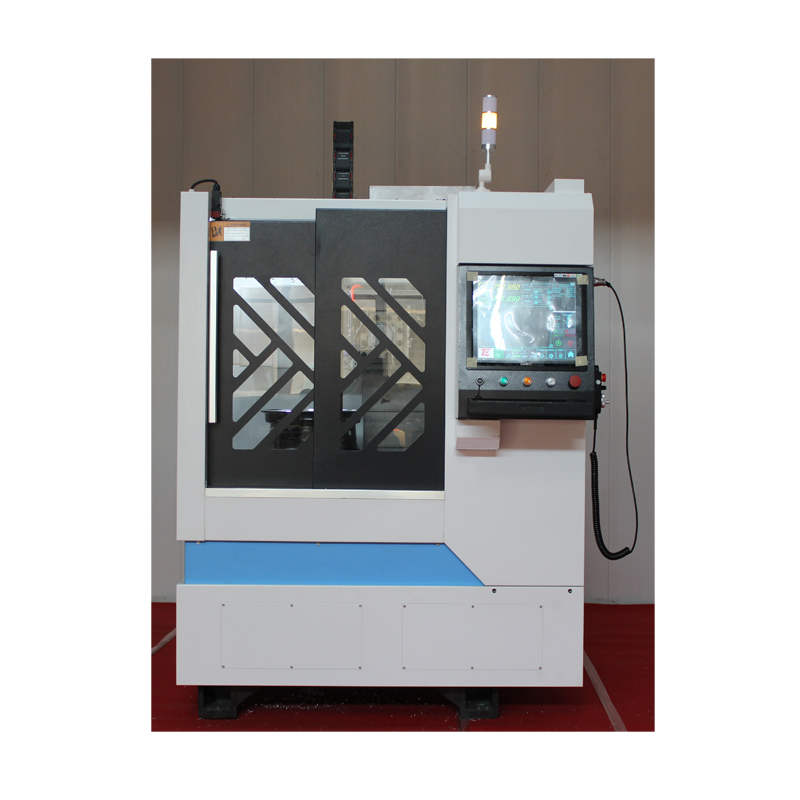

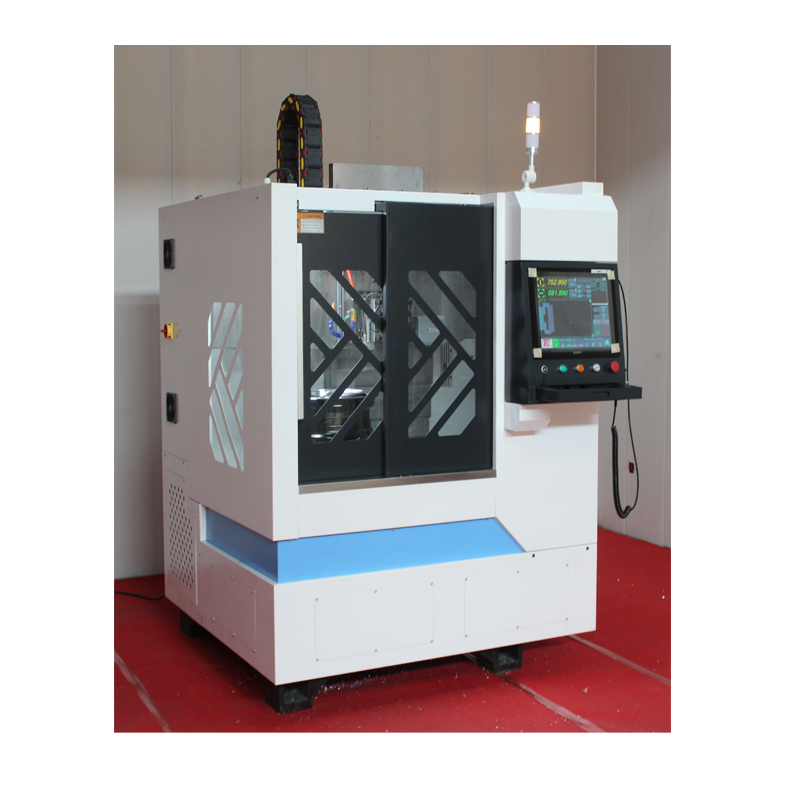

2. Main features

1) High precision: The advanced servo drive system and precision guide rails are used to ensure the accuracy and stability of the cutting process.

2) Multi-function: In addition to the basic cutting function, it also has a variety of processing functions such as drilling and milling to meet the repair needs of different wheel hub damage types.

3) Automation: Through the CNC control system, automatic processing is realized to improve production efficiency and processing quality.

4) Wide adaptability: Suitable for wheel hub repair of various materials such as aluminum alloy, magnesium alloy, and steel.

3. Application advantages

1) Improve repair efficiency: Automated processing and precise trajectory detection greatly shorten the time of wheel hub repair.

2) Improve repair quality: High-precision cutting ensures that the surface of the repaired wheel hub is flat and smooth, restoring the original beauty and performance.

3) Reduce costs: Compared with traditional manual repair methods, wheel hub repair surface cutting lathes can reduce repair costs and improve economic benefits.